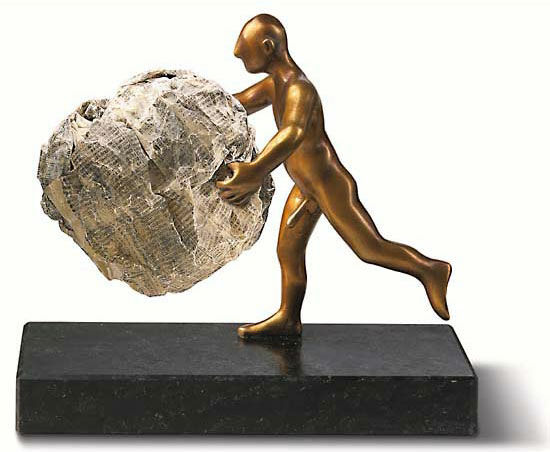

Sculpture "Messenger", bronze version

Sculpture "Messenger", bronze version

Quick info

limited, 99 copies | numbered | signed | bronze + diabase | handmade | total height 17.5 cm

Detailed description

Sculpture "Messenger", bronze version

"Hermes" messages in a completely different way: this is how the messenger of the gods of classical antiquity delivers the news of the day in the form of a newsprint ball. Tamar succeeds in a wonderfully humorous way in symbolising our transitory media world. Height incl. diabase pedestal 17.5 cm. Base size 20 x 3 x 8,5 cm (w/h/d).

Edition in fine bronze. Limited edition of 99 copies, cast by hand using the Lost-Wax-Process. Signed and numbered.

Producer: ars mundi Edition Max Büchner GmbH, Bödekerstraße 13, 30161 Hanover, Germany Email: info@arsmundi.de

About Julius Thomas Tamar

Tamar was born in 1949 in Silesia and now lives in Münster, Germany. He was always a real rouge. And so, he has already provoked and surprised the art world with humour and imagination at numerous exhibitions in Germany, Poland, France, Italy, Hungary, Russia and Yugoslavia.

In his objects, Julius Thomas Tamar combines classical motifs with his very own, always from a humorous point of view. In this way, he creates sculptures of exceptional loveliness. No wonder that his objects can already be found in numerous private and public collections in Western and Eastern Europe and the USA.

An alloy of copper with other metals (especially with tin) used since ancient times. It is an ideal metal for high-quality artistic castings, capable of enduring for millennia.

When casting bronze, the artist usually applies the lost-wax technique which is dating back more than 5000 years. This is the best, but also the most complex method of producing sculptures.

First, the artist forms a model of their work. This model is embedded in a liquid silicone rubber mass. Once the material has solidified, the model is cut out, leaving a negative mould. Liquid wax is then poured into the negative mould. After cooling down, the wax cast is removed from the mould, provided with sprues and dipped into ceramic mass. The ceramic mass is hardened in a kiln, where the wax melts away (lost mould).

Finally, the negative mould is ready, into which the 1400° C hot molten bronze is poured. After the bronze had cooled down, the ceramic shell is broken apart, reavoling the sculpture.

Next, the sprues are removed, the surfaces are polished, patinated and numbered by the artist or by a specialist, following their instructions. Thus, each casting is an original work.

For lower-quality bronze castings, the sand casting method is often used, which, however, does not achieve the results of a more elaborate lost-wax technique in terms of surface characteristics and quality.

Term for an art object (sculpture, installation) that, according to the artist’s intention, is produced in multiple copies within a limited and numbered edition.

Multiples enable the "democratization" of art by making the work accessible and affordable for a wider audience.

A plastic work of sculptural art made of wood, stone, ivory, bronze or other metals.

While sculptures made of wood, ivory, or stone are carved directly from the material block, in bronze casting, a working model is prepared at first. Usually, it is made of clay or other easily mouldable materials.

The prime time of sculpture after the Greek and Roman antiquity was the Renaissance. Impressionism gave a new impulse to the sculptural arts. Contemporary artists such as Jorg Immendorf, Andora, and Markus Lupertz also enriched sculptures with outstanding works.